Ozone India Technology is proud to announce the successful sale and installation of a state-of-the-art UV sterilization chamber at the Air Force base in Gwalior. This achievement highlights our ongoing commitment to providing reliable and efficient disinfection solutions to high-security and defence environments. The UV chamber ensures effective sterilisation of equipment and materials, helping maintain strict hygiene protocols without the use of chemicals. While this particular project did not include an ozone generator, our expertise spans both UV and ozone-based technologies, making Ozone India Technology a trusted partner in advanced sterilisation and purification solutions across India. Let’s take a detailed look at how we gain such a valuable client and how we serve them.

What is a UV Sterilization Chamber?

A UV sterilization chamber is a specially designed enclosed unit that uses powerful UV-C light to disinfect and kill harmful microorganisms like bacteria, viruses, and fungi. UV-C light has a short wavelength that penetrates the DNA or RNA of these microbes, effectively destroying their ability to reproduce and spread. Items placed inside the chamber—such as files, uniforms, tools, or electronic devices—are exposed to this germicidal light for a set time, ensuring thorough sterilisation without the use of heat or chemicals. These chambers are widely used in defence facilities, hospitals, pharmaceutical industries, research labs, and other sensitive environments where hygiene and contamination control are critical.

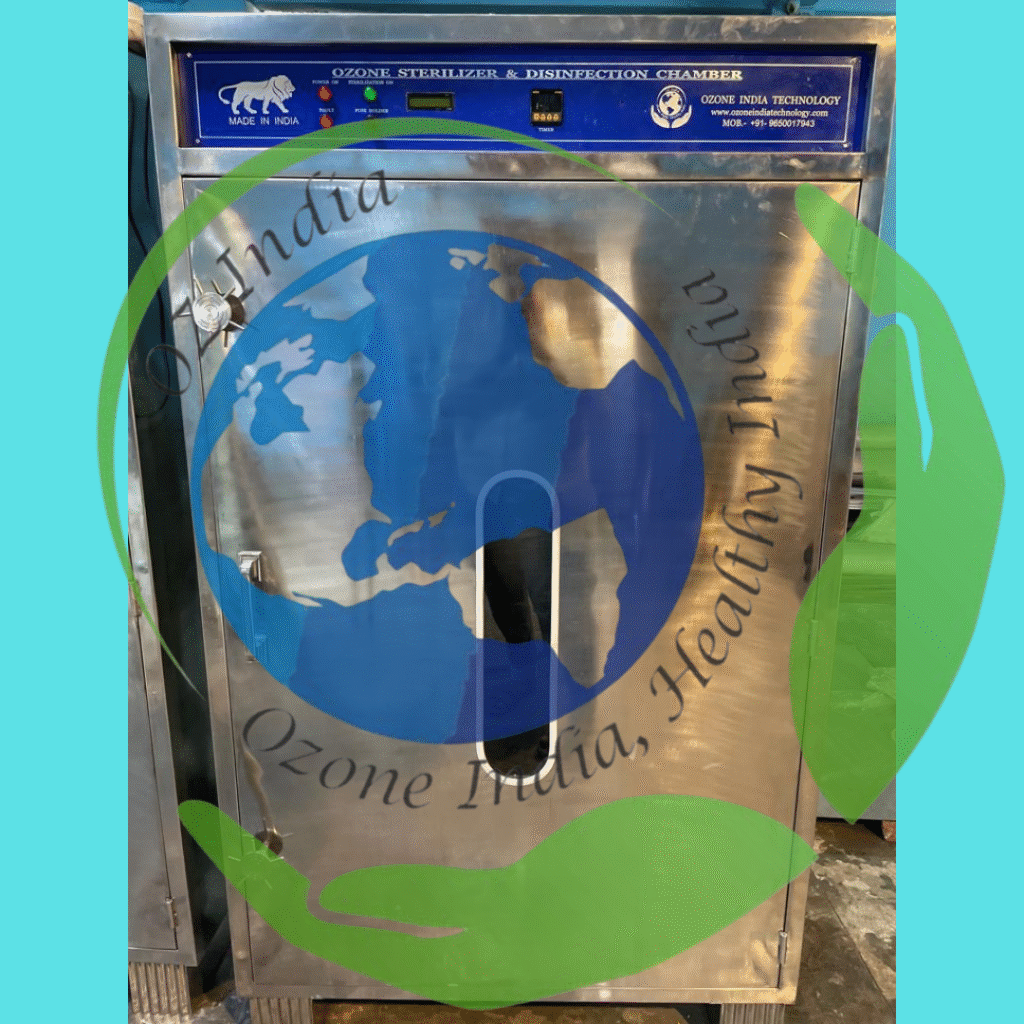

Unlike standard products in the market, the UV sterilization chamber from Ozone India Technology is designed with a focus on both performance and practicality. Our chamber is built using high-grade stainless steel for durability and reflects UV light evenly for complete 360° sterilisation. It features industrial-grade UV-C lamps with optimal wavelength (254 nm) to ensure maximum microbial kill rate within minutes. The chamber also includes safety interlocks, user-friendly controls, and customizable sizes to meet different institutional needs. Whether used in defence, labs, or healthcare, our chamber delivers consistent results with minimal maintenance, making it a reliable and cost-effective solution compared to others in the market.

We built this sterilisation chamber by having this in mind that we are serving the nation, and we have to provide the best quality and price when it comes to national security. We always think that every client is important and we are always able to cater them with our customised solution for your needs. We also serve in a big five-star hotel. Let’s dig deep into how the UV Sterilisation chamber works.

How a UV Sterilization Chamber Works?

A UV sterilization chamber operates by using UV-C light, which falls in the 200–280 nanometer (nm) wavelength range, specifically designed to kill or inactivate microorganisms. When items such as tools, files, electronic devices, or clothing are placed inside the chamber and the system is activated, the UV-C lamps emit radiation at around 254 nm, which is highly effective in disrupting the DNA or RNA structure of pathogens like bacteria, viruses, and fungi.

Step-by-Step Breakdown: How a UV Sterilization Chamber Works

- Loading the Chamber

Items that need disinfection—such as mobile phones, tools, ID cards, documents, lab instruments, or PPE—are placed inside the UV sterilization chamber. Most chambers include stainless steel racks or perforated trays to allow 360-degree exposure of UV-C light. It’s important that items are spaced evenly so no shadow zones are created. - Chamber Sealing

Once the door is securely closed, the chamber is sealed completely. High-quality UV chambers like those from Ozone India Technology use magnetic gaskets or mechanical locks to prevent UV-C leakage. A safety interlock ensures the UV-C lamps cannot be turned on unless the door is closed, protecting the user from harmful exposure. - Activation of UV-C Lamps

When the cycle is started, UV-C lamps (typically emitting at 254 nanometers) are activated. These lamps generate germicidal light that disrupts the DNA and RNA of microorganisms such as bacteria, viruses, mould spores, and fungi. The reflective interior walls help bounce the UV-C light, ensuring maximum surface coverage. - Disinfection Process

The UV-C light penetrates the cell walls of pathogens and damages their genetic material. This effectively inactivates the microorganisms, making them incapable of reproduction or infection. The duration of the exposure—usually 5 to 15 minutes—is calibrated based on item type, load size, and lamp intensity to ensure over 99.9% microbial reduction. - Automatic Shutoff or Timer

The chamber is programmed to operate for a set sterilization cycle. Once the timer ends, the UV-C lamps switch off automatically. Some advanced models also include buzzers or indicator lights to signal the end of the cycle. This ensures both operational ease and safety. - Safe Removal

Once the cycle is complete, items can be removed immediately. Unlike chemical disinfectants, UV sterilization leaves no residue, smell, or moisture, making it ideal for electronics, sensitive tools, and daily-use objects. The chamber is ready for the next cycle with minimal downtime.

This chemical-free process is highly efficient and ideal for sensitive environments like defence installations, hospitals, research labs, and pharmaceutical facilities. The UV sterilization chamber from Ozone India Technology ensures high-intensity UV exposure, even distribution, and built-in safety mechanisms, making it both effective and user-friendly.

Our Experience

The recent installation of our UV sterilization chamber at the Air Force base in Gwalior marks a proud moment for Ozone India Technology. Serving one of the country’s most disciplined and high-security institutions, this project showcases our commitment to national hygiene and defence readiness. The chamber supplied was a medium-capacity model, designed to handle a wide variety of items—from personal belongings to sensitive instruments—within a stainless-steel, reflective enclosure for uniform UV-C exposure.

From initial inquiry to final commissioning, the entire process of delivering and installing the UV sterilization chamber at Air Force Gwalior was completed in just a couple of working days—a testament to the efficiency and coordination of Ozone India Technology’s operations and technical teams. This tight timeline included every critical stage: custom design, precision manufacturing, strict quality inspections, and final on-site installation. A major challenge during the project was the spatial limitation within the designated defence facility. Our engineering team had to ensure the chamber would fit seamlessly into an existing operational area without requiring structural modifications.

Thanks to our in-house design experts and the agility of our production unit, we were able to customise the chamber’s size and internal layout, while maintaining the same high-performance standards. What truly sets us apart is our dedicated quality management team, which ensures every unit passes through multi-level checks for UV-C intensity, material integrity, electrical safety, and user protection. Before dispatch, our chamber underwent simulated testing to guarantee that it could withstand continuous use in a high-demand environment like a military base. The result was a fully compliant, high-efficiency UV sterilization chamber that met the Air Force’s expectations for performance, safety, and durability. This successful deployment reinforces the position of Ozone India Technology as a trusted partner for advanced disinfection systems in sensitive and mission-critical sectors across India.

Why Choose Ozone India Technology?

1. Superior Product Quality

At Ozone India Technology, every UV sterilization chamber is built using industrial-grade stainless steel and tested for durability, effectiveness, and safety. Our in-house quality management team conducts multi-level checks for UV-C output, timer accuracy, and interlock mechanisms to ensure maximum disinfection with zero compromise.

2. Fast Turnaround Time

We understand the urgency in sectors like defence, healthcare, and pharmaceuticals. That’s why we offer one of the fastest response-to-delivery cycles in the industry. From custom design to installation, our recent project at Air Force Gwalior was completed in just couple of working days—including manufacturing and customising.

3. Customisation Capability

Our team specialises in designing UV sterilization chambers that meet specific space, volume, and safety requirements. Whether it’s a compact unit for labs or a larger chamber for industrial use, we provide tailor-made solutions without sacrificing performance.

4. Expert Service & Support

We offer end-to-end support—from product consultation to post-installation maintenance. Our trained technicians and service engineers ensure smooth operations, while our customer care team provides quick resolutions and guidance.

5. Proven Track Record

In addition to the Gwalior Air Force project, Ozone India Technology has delivered successful installations to several hospitals, pharma companies, and government research labs. Our reputation is built on trust, quality, and performance.

6. Beyond UV: Complete Disinfection Solutions

While this project focused on UV technology, Ozone India Technology is also a recognised provider of ozone generators and integrated air-water purification systems, offering clients a complete range of eco-friendly sterilization options.

7. Future Outlook

With the growing need for non-chemical disinfection across industries, we’re expanding our product line to include hybrid sterilisation systems, humidity chambers, smart monitoring features, and silver ionisation systems. Our goal is to set new benchmarks in safety, sustainability, and innovation.

Conclusion

The successful installation of our UV sterilization chamber at the Air Force base in Gwalior is more than just a milestone—it’s a demonstration of Ozone India Technology’s commitment to delivering world-class disinfection solutions to India’s most respected institutions. From fast execution to precise customisation, this project reflects our technical expertise, quality assurance, and customer-first approach.

As the need for reliable, chemical-free sterilization continues to rise, we aim to bring our innovative technologies—ranging from UV sterilization chambers to advanced ozone generators—to more defence units, hospitals, pharmaceutical companies, and research labs across the country.

If your institution is looking for powerful, eco-friendly sterilization systems, Ozone India Technology is ready to help.

Contact us today to explore our full range of UV and ozone-based solutions and experience the future of disinfection technology.