In an era of increasingly stringent environmental regulations and growing sustainability demands, traditional wastewater treatment methods are no longer sufficient. Across industries and municipalities, water treatment plants are under growing pressure to tackle emerging contaminants like pharmaceuticals, hormones, and microplastics — all while improving operational efficiency and minimizing ecological footprints.

This is where ozone generators are redefining the future of advanced wastewater treatment.

Why Now?

The global ozone generator market surpassed USD 441.9 million in 2024 and is projected to grow at a CAGR of over 7% from 2025 to 2034, driven by regulatory mandates and rising adoption across municipal, industrial, and commercial segments.

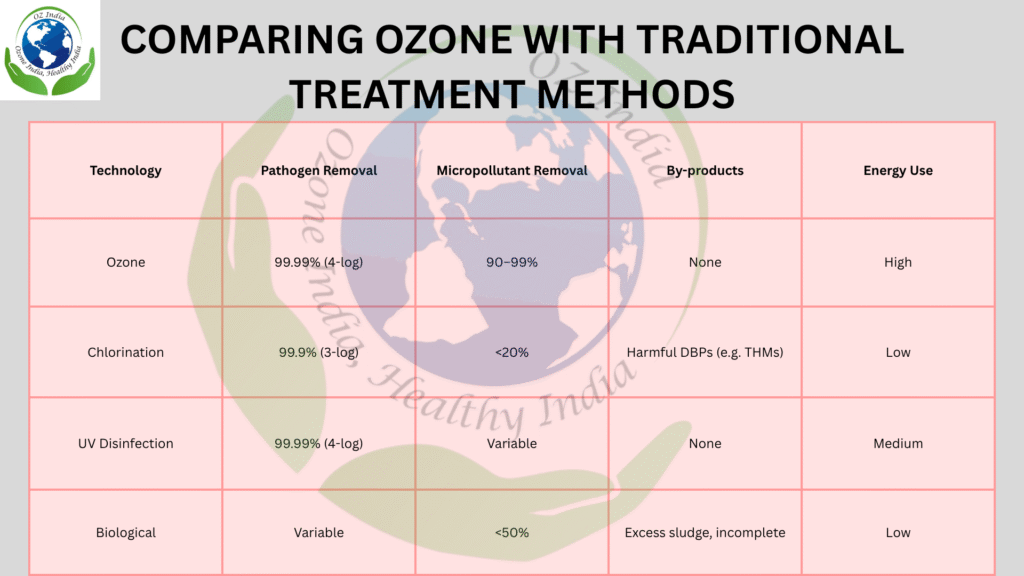

Ozone, a powerful oxidant with a redox potential of 2.07V (far higher than chlorine’s 1.36V), has emerged as a superior alternative for disinfecting and detoxifying wastewater, from municipal sewage to complex industrial effluents. It not only removes persistent micropollutants and eliminates pathogens but also breaks down harmful compounds without generating toxic by-products.

The future of wastewater purification is oxidative, sustainable, and data-driven, and ozone is leading the charge.

How Ozone Works in Wastewater Treatment?

Ozone (O₃) is a triatomic molecule consisting of three oxygen atoms, distinguished by its powerful oxidative capabilities. It is naturally present in the Earth’s stratosphere, where it forms the ozone layer that shields life from harmful ultraviolet (UV) rays. In industrial applications like wastewater treatment, ozone is produced on-site using ozone generators, typically through methods such as corona discharge or ultraviolet radiation, which convert oxygen molecules (O₂) into ozone.

Ozone acts as a strong oxidising agent due to its unstable molecular structure, which readily breaks down to release a single oxygen atom. This atomic oxygen aggressively reacts with pollutants, breaking chemical bonds in organic and inorganic contaminants, microorganisms, and other hazardous substances. The oxidation reactions effectively degrade complex molecules like pesticides, pharmaceuticals, dyes, and industrial chemicals into harmless by-products such as carbon dioxide, water, and oxygen. This makes ozone a highly effective disinfectant and deodoriser without leaving persistent chemical residues.

The efficiency of ozone treatment depends on several operational parameters. These include ozone concentration, contact time between ozone and wastewater, water temperature, pH levels, and the presence of substances that can act as ozone scavengers (e.g., certain ions or organic matter). Higher ozone dosages and longer contact times increase pollutant removal but also raise operational costs, so treatment systems are designed to balance effectiveness and efficiency. Ozone’s ability to kill bacteria, viruses, and protozoa also enhances the biological safety of treated water, making it suitable for reuse in industrial processes or even as potable water after further treatment.

Moreover, ozone treatment has advantages over traditional disinfectants like chlorine. Unlike chlorine, which can produce harmful disinfection by-products such as trihalomethanes (THMs), ozone decomposes quickly and does not leave toxic residues in the treated water. This makes ozone treatment an environmentally sustainable solution that aligns with stricter regulatory standards on water quality and chemical use. For more related information.

Overall, ozone’s powerful oxidation capacity combined with its environmentally friendly nature makes it a preferred choice for advanced wastewater treatment, helping industries comply with discharge regulations and supporting water reuse initiatives.

Applications of Ozone Generators in Wastewater Treatment

Ozone generators are widely used in various wastewater treatment applications due to their strong oxidative and disinfectant properties. One primary application is the removal of organic pollutants, including dyes, pharmaceuticals, and industrial chemicals that are often resistant to conventional treatment methods. By breaking down these complex molecules, ozone helps reduce the chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of wastewater, improving overall water quality before discharge or reuse.

In addition to organic pollutant removal, ozone is highly effective in disinfecting wastewater by inactivating bacteria, viruses, and protozoa, which are major sources of waterborne diseases. This makes ozone treatment particularly valuable in municipal sewage treatment plants and industries where microbial contamination is a concern, such as food processing and healthcare facilities.

Another important use of ozone generators is in the reduction of color and odor in wastewater. Many industrial effluents contain colored compounds from dyes and pigments that affect the aesthetic and environmental acceptability of discharged water. Ozone’s oxidation reactions break down these chromophores, significantly reducing color and eliminating unpleasant odors. This is crucial for meeting regulatory requirements and minimising the environmental impact on receiving water bodies.

Ozone also plays a role in sludge reduction and improvement of sludge dewaterability, which helps lower sludge disposal costs and enhances the efficiency of sludge handling processes. Furthermore, ozone treatment can serve as a pretreatment step before biological treatment, making the organic matter more biodegradable and improving the performance of downstream biological reactors.

Industries such as textile manufacturing, petrochemicals, pharmaceuticals, and pulp and paper frequently rely on ozone generators for these applications. Additionally, with increasing emphasis on water reuse, ozone treatment is becoming essential in producing high-quality reclaimed water suitable for irrigation, cooling, or even potable purposes after further purification.

Overall, the diverse applications of ozone generators in wastewater treatment underscore their importance as a versatile and eco-friendly technology capable of addressing complex water pollution challenges across multiple sectors.

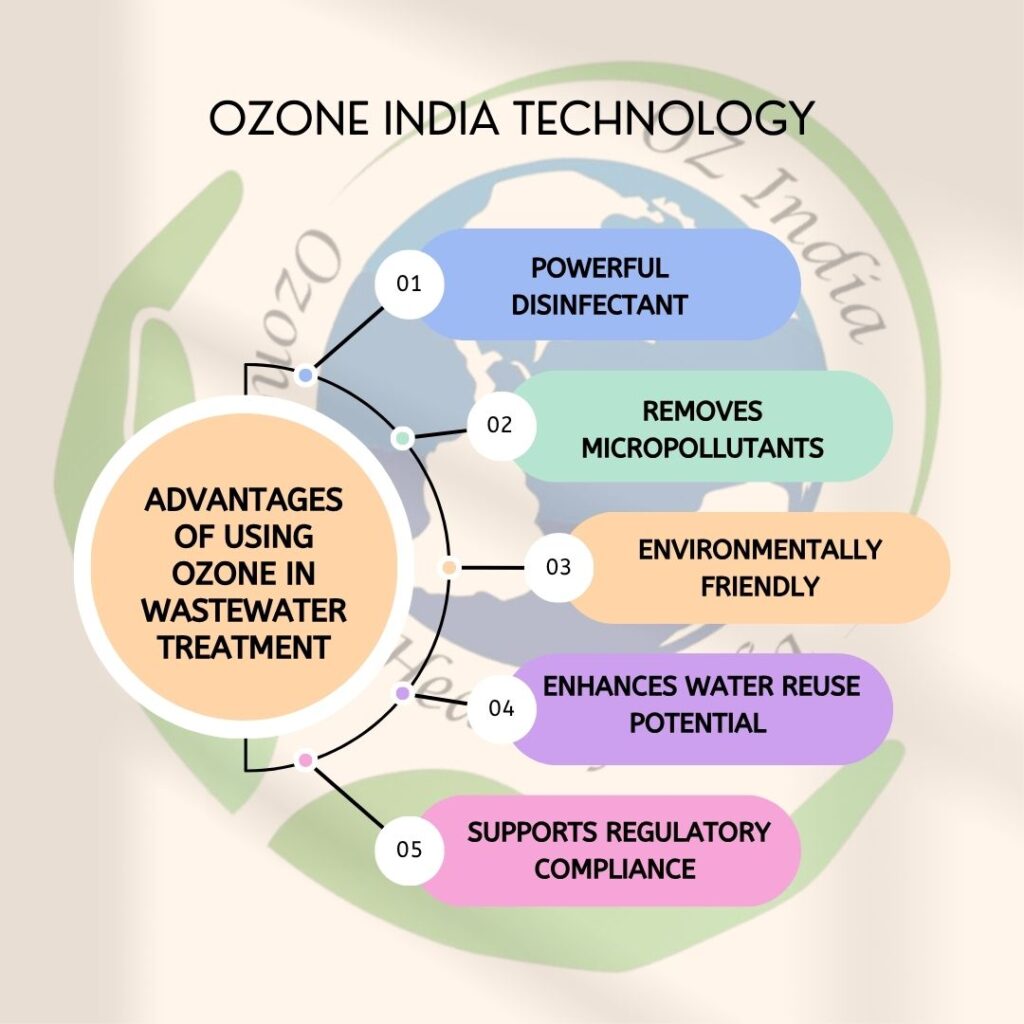

Advantages of Using Ozone Generators in Wastewater Treatment

Ozone generators offer several advantages that make them an attractive choice for wastewater treatment processes. Ozone is a powerful oxidizing agent with an oxidation potential of 2.07 volts, which is higher than chlorine (1.36 volts) and hydrogen peroxide (1.78 volts), allowing it to effectively degrade a wide range of organic and inorganic contaminants. This enables treatment of complex pollutants that often resist conventional methods, ensuring up to 99% removal of contaminants such as pesticides, pharmaceuticals, and color-causing compounds.

A major advantage of ozone treatment is that it does not leave harmful chemical residues. Unlike chlorine-based disinfectants that can produce toxic chlorinated by-products like trihalomethanes (THMs), ozone decomposes into oxygen after reacting with pollutants, making it environmentally safe. This is particularly important in industries aiming to meet stricter discharge standards, such as the US EPA regulations, which limit THMs to 80 parts per billion (ppb).

Ozone is also very effective at disinfecting wastewater, rapidly inactivating bacteria, viruses, and protozoa. Studies show ozone can achieve up to a 5-log reduction (99.999% kill) of pathogens like E. coli and Giardia lamblia within minutes, significantly faster than traditional chlorination methods that may require 30 minutes or more.

In addition to disinfection, ozone reduces odor and color in wastewater by breaking down compounds that cause unpleasant smells and coloration. For example, ozone treatment can reduce color by up to 80% and chemical oxygen demand (COD) by 30-50%, enhancing the aesthetic quality of treated water for reuse applications. It also improves sludge management by degrading complex organic matter, resulting in up to 20% reduction in sludge volume, which lowers disposal costs and environmental impact.

Ozone generators can be integrated into existing wastewater systems with flexibility. Their use in advanced oxidation processes (AOPs) combined with UV or hydrogen peroxide further improves treatment efficiency, enabling the breakdown of persistent organic pollutants that are difficult to remove by conventional means.

Though the initial cost of ozone generators ranges between $0.5 to $1.5 per cubic meter of treated water, the reduced need for chemical additives, lower sludge handling costs, and compliance with environmental regulations provide long-term economic benefits. The energy consumption of ozone generation typically varies between 8 to 15 kWh per kilogram of ozone produced, which is competitive compared to other oxidation technologies.

Overall, ozone generators present a sustainable and highly effective technology for modern wastewater treatment, helping industries and municipalities achieve cleaner effluents and environmental protection goals.

Challenges and Limitations of Ozone Generators in Wastewater Treatment

Despite the many advantages of using an ozone generator for wastewater treatment, there are several challenges and limitations that must be considered to ensure effective application. One significant challenge is the relatively high energy consumption required to produce ozone. The process of generating ozone through an industrial ozone generator water treatment system involves passing oxygen or air through a high-voltage electrical discharge, consuming between 8 to 15 kWh per kilogram of ozone produced. This energy demand can increase operational costs, especially for large-scale plants treating millions of liters of wastewater daily.

Another limitation is the short half-life of ozone in water, which affects the efficiency of ozone wastewater treatment. Ozone rapidly decomposes within 20 to 30 minutes in aqueous solutions, meaning it must be generated on-site and applied immediately for effective treatment. This short lifespan also limits ozone’s ability to provide residual disinfection, unlike more stable chemicals such as chlorine.

The use of ozone disinfection in wastewater treatment can sometimes lead to the formation of harmful by-products. For example, ozone can react with bromide ions present in wastewater to form bromate, a regulated carcinogen. Regulatory agencies, such as the US EPA, set strict limits for bromate concentration (10 ppb), making monitoring essential during ozone treatment processes.

Additionally, the complexity of ozone generator wastewater treatment systems requires skilled operation and higher capital investment compared to traditional chemical disinfectants. Proper system design and maintenance are critical, especially as wastewater characteristics such as pH, temperature, and organic load can affect ozone’s performance.

In some industrial settings, industrial ozone generators for water treatment may not be sufficient alone to meet all treatment objectives. Combining ozone treatment with other processes, like biological treatment or advanced oxidation processes, is often necessary to achieve desired contaminant removal levels.

Safety is also a critical consideration. Ozone is a toxic gas at high concentrations, so proper ventilation, monitoring, and safety protocols are essential to protect workers during ozone wastewater treatment operations.

In conclusion, while ozone generator wastewater treatment offers effective pollutant removal and disinfection, challenges such as energy use, ozone’s short half-life, by-product formation, operational complexity, and safety need to be carefully managed to maximise benefits.

Regulatory Considerations and Safety Standards

The use of ozone generators in wastewater treatment is governed by a variety of regulatory frameworks and safety standards to ensure both environmental protection and worker safety. Since ozone is a powerful oxidizing agent, its handling, storage, and application require strict compliance with established guidelines.

In India, the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) oversee the implementation of standards related to water and air quality. Globally, organizations like the U.S. Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and the European Environment Agency (EEA) have issued detailed safety protocols for ozone wastewater treatment systems. For example, OSHA mandates that workplace exposure to ozone must not exceed 0.1 ppm over an 8-hour shift. This ensures that operators working near industrial ozone generator water treatment systems are not exposed to harmful levels of ozone.

Additionally, the use of ozone disinfection wastewater technology must comply with effluent discharge standards. In India, treated wastewater must meet the limits set under the Environmental Protection Rules (1986), including parameters like Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD), Total Suspended Solids (TSS), and coliform count. Ozone wastewater treatment is especially effective in helping meet these parameters, often reducing BOD and COD by up to 90%, depending on the input water quality and treatment design.

Manufacturers of industrial ozone generators for water treatment are also expected to comply with international safety certifications like CE (European Conformity), UL (Underwriters Laboratories), and ISO 9001 for quality management. These certifications ensure that ozone systems are safe, reliable, and efficient for both industrial and municipal applications.

Adherence to regulatory standards not only ensures environmental sustainability but also builds credibility for industries deploying advanced treatment methods like ozone generator wastewater treatment. For plant operators and engineers, routine ozone leak detection, proper ventilation, and system monitoring using ozone sensors are critical components of safe operation. Many modern systems are equipped with automatic shutdown features and alarms to mitigate the risks of ozone exposure.

As governments around the world tighten environmental regulations and demand higher standards for wastewater reuse and discharge, ozone technology continues to gain favor. However, it’s vital that industries stay updated with changing guidelines and invest in systems that are not only high-performing but also compliant with evolving safety and environmental norms.

Integration with Existing Wastewater Treatment Systems

One of the key strengths of ozone wastewater treatment is its flexibility and ease of integration with existing infrastructure. Rather than requiring a complete overhaul of traditional treatment setups, ozone generator wastewater treatment systems can often be added as a complementary or final polishing step in the treatment process.

Most commonly, ozone is introduced in the tertiary treatment stage—after primary sedimentation and secondary biological treatment. In this stage, ozone acts as a powerful disinfectant and oxidizer, breaking down residual organic compounds, removing color, and eliminating pathogens. This makes ozone disinfection wastewater technology an ideal solution for industries aiming to meet stringent discharge or reuse standards.

Integration typically involves installing an industrial ozone generator for water treatment, a contact chamber or diffuser system, and control units for ozone dosage and monitoring. These systems can be scaled based on the flow rate and quality of wastewater. For example, at OIT’s deployment in the Durgapur Steel Plant, the ozone unit was integrated seamlessly with the plant’s existing clarifiers and biological treatment setup—resulting in an ROI within 22 months and a 65% reduction in sludge volume.

Importantly, ozone systems are modular and can be customized for a variety of industry-specific needs—be it in textiles, pharmaceuticals, steel, or food processing. This adaptability reduces the initial investment costs, minimizes downtime during implementation, and allows industries to adopt advanced treatment without disrupting their operations.

Another advantage is that ozone does not introduce any new chemicals into the system, unlike chlorine or other conventional disinfectants. This means there’s no risk of forming harmful byproducts like trihalomethanes (THMs), which simplifies post-treatment handling and disposal. Furthermore, excess ozone decomposes back into oxygen, making it an environmentally sustainable choice.

Overall, integrating ozone generator wastewater treatment solutions into existing plants offers industries a cost-effective, eco-friendly, and highly efficient method to enhance water treatment outcomes—especially as regulatory pressures and sustainability goals continue to rise.

Sustainability and Environmental Impact

Ozone wastewater treatment stands out not only for its effectiveness but also for its strong alignment with environmental sustainability goals. As industries across the globe strive to reduce their ecological footprints, ozone disinfection wastewater systems offer a clean and green alternative to conventional chemical treatments.

Unlike chlorine or other chemical disinfectants, ozone decomposes naturally into oxygen after its reactive work is done. This means it does not leave behind harmful residues or create toxic byproducts like chlorinated organics or trihalomethanes (THMs). This attribute significantly lowers the burden on post-treatment processes and reduces the risk of environmental contamination.

Moreover, industrial ozone generator water treatment systems contribute to lower chemical consumption and minimal sludge generation. Traditional chemical treatments often result in large amounts of sludge that require additional handling and disposal, increasing both costs and environmental impact. In contrast, ozone oxidation breaks down pollutants at the molecular level, reducing sludge volume by up to 60% in many industrial applications.

From a resource efficiency perspective, modern ozone generator wastewater treatment technologies are increasingly energy-efficient. Advanced systems are designed to produce ozone on-site using ambient air or oxygen with optimized power consumption. This avoids the need for transporting or storing hazardous chemicals and significantly reduces the system’s carbon footprint.

Many companies are also leveraging ozone as part of their water reuse strategies. Treated effluent using ozone can be recycled for cooling, cleaning, or even irrigation—supporting circular water management models. For example, in the textile and paper industries, ozone-treated water has been reused for internal processes, helping reduce freshwater intake by up to 40%.

Lastly, regulatory bodies like the U.S. EPA and the European Union recognize ozone as a safe and effective disinfectant. This regulatory acceptance helps industries stay compliant with evolving environmental standards while positioning themselves as sustainable leaders in their sectors.In summary, the adoption of ozone wastewater treatment systems not only enhances water quality but also aligns with global sustainability objectives. By reducing chemical usage, lowering sludge volumes, and enabling water reuse, ozone technology is a key enabler for eco-friendly industrial operations.

Conclusion and Future Outlook

Ozone generators in wastewater treatment represent a transformative advancement in the field of industrial water purification. Their ability to deliver high-efficiency pollutant breakdown, strong disinfection power, and environmentally sustainable outcomes makes them an increasingly popular choice across industries like textiles, food processing, pharmaceuticals, and steel manufacturing.

As we’ve seen throughout this guide, ozone wastewater treatment offers several advantages over traditional methods: it produces no harmful byproducts, reduces chemical and sludge handling costs, and achieves higher oxidation and disinfection levels. With the help of advanced industrial ozone generator water treatment systems, companies can now achieve stricter compliance standards while improving operational efficiency.

The future of ozone generator wastewater treatment looks promising, with ongoing innovations in energy-efficient ozone generation, AI-driven monitoring systems, and modular treatment designs. These improvements are expected to reduce costs further and make the technology accessible even for small and medium-sized enterprises. Additionally, increasing global emphasis on water reuse and zero-liquid discharge (ZLD) will likely accelerate the adoption of ozone-based systems.

Environmental regulations and sustainability goals are also key drivers. As regulatory bodies impose stricter effluent standards and carbon reduction targets, industries will continue to seek advanced solutions like ozone disinfection wastewater systems to stay competitive and responsible.

In conclusion, the role of ozone in industrial wastewater treatment is no longer limited to niche applications. It has become a mainstream, data-backed, and results-oriented technology. Businesses that invest in ozone systems not only safeguard water resources but also future-proof their operations in a rapidly changing environmental and regulatory landscape.